Industrial Vibrators Help Keep the Lights On

Moving coal through a coal fire power plant is critical to efficient power generation Like many bulk materials, a major factor in how coal is moved through the processes is the weather. Increases in moisture can cause material to become more difficult to flow through equipment like bunkers, hoppers and chutes. In times of high moisture, coal will begin to build on the walls of the vessels which leads to plugging and a reduction or halt in production until the issue can be addressed.

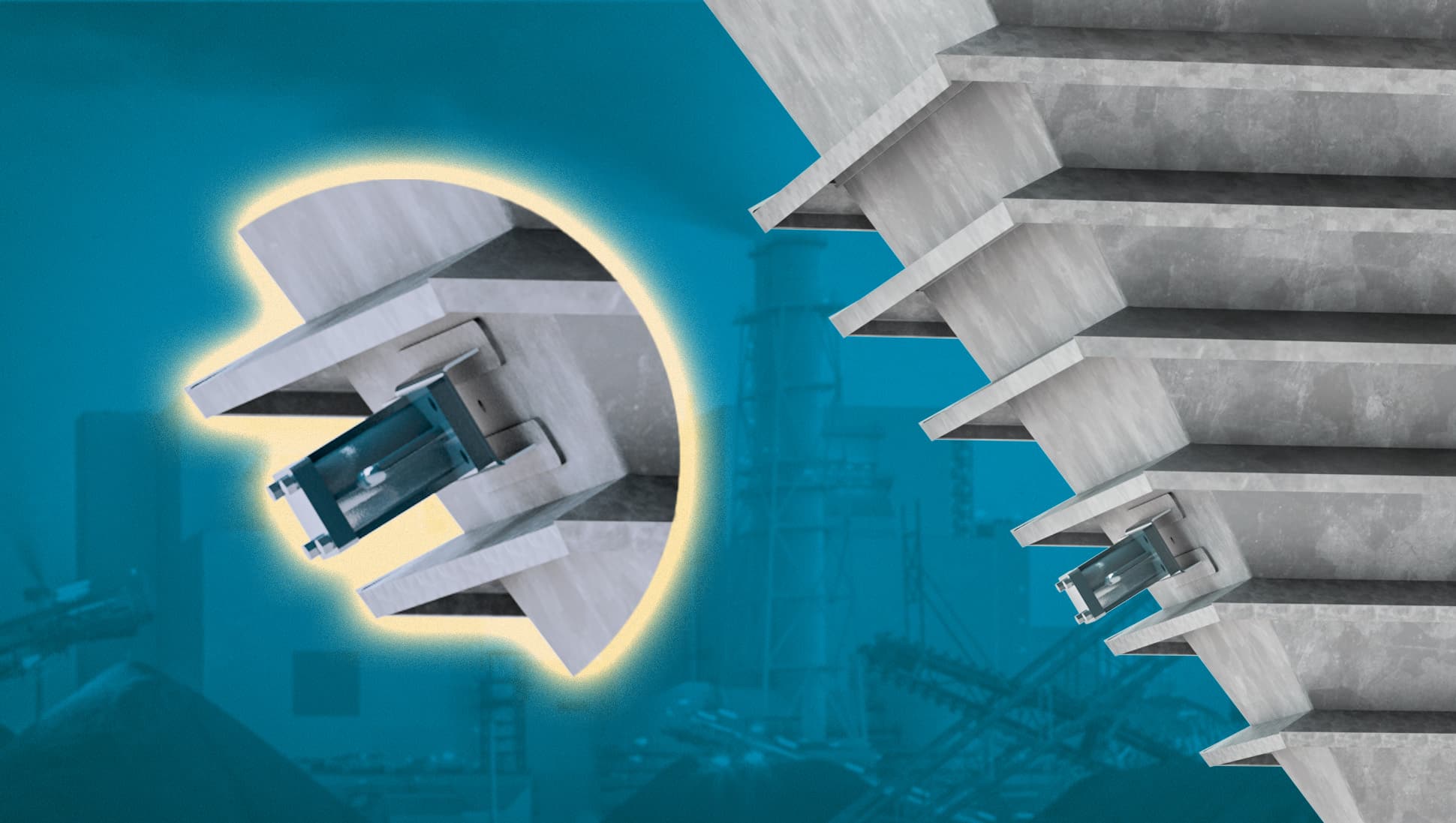

A coal fired generating plant recently reached out to Wm. Neundorfer & Co. for help to overcome plugging in several coal chutes above their feed mills during inclement weather. After reviewing the plants processes and material issues as well as examining drawings of the coal handling stream, Wm. Neundorfer & Co. put together a pneumatic vibrator package to address their issue. The package included 14 bin hopper vibrators with tapped exhausts placing two vibrators on each chute.

Pneumatic piston bin hopper vibrators were selected for their ability to transmit vibrational energy efficiently through chute walls and into the sticking / plugging material. The energy reduces the sliding friction of the wall and the material causing the plugged material to collapse and begin to flow. Tapped exhausts ports were proposed to provide increased protection against foreign material intrusion.

In addition to providing an equipment package, Wm. Neundorfer & Co. also supplied a bin map analysis with suggested vibrator mounting locations on the chutes. This analysis assesses plugging issues, the chute, and the selected vibrators to create a bin map diagram that denotes optimal vibrator placement on the chute and operating parameters.

The plant agreed with Wm. Neundorfer & Co.’s proposed package but wanted to run a trial on one of the chutes to run comparison tests versus chutes without the vibrators. Two vibrators were installed on a chute and the plant ran as normal for a few months. The plant saw an immediate positive effect from the vibrators. The trial chute saw reduced plugging and experienced fewer material flow problems than previously experienced prior to installation of the piston vibrator system. Pleased with the results of the vibrators in the trial the plant ordered vibrators for the remaining chutes.

For more information or details on how we can help you select the right equipment for your application, contact Wm Neundorfer & Co today.

We have the expertise and experience to ensure you get the advice and recommendations you require for your specific application.