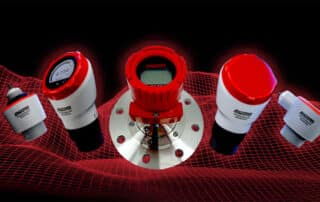

BinMaster’s BinCloud®: Advanced Bin Management and Bulk Material Handling

BinMaster’s BinCloud® revolutionizes bin management by combining advanced software with real-time monitoring solutions to streamline silo volume measurement, remote bin tracking, and bulk material handling. Wm. Nuendorfer & Co. has been a long-time partner of BinMaster and in this article we will highlight the [...]