Key Features to look for in Horizontal Shaft Mixers

Horizontal shaft mixers are used to mix product for a wide range of applications including precast, dry bagging, transit mixes and specialty mixes. Choosing the correct horizontal shaft mixer to meet the demands of your application is critical for ensuring a high-quality mix and safe operation. Wm. Neundorfer & Co. has been helping our customers improve their industrial processes for over 50 years. In this article, we will discuss the features to look for in a horizontal shaft mixer to help ensure quality products and improve operational safety.

Steel, Dust-Tight Gasketed Access Doors

The inclusion of steel, dust-tight gasketed access doors in Horizontal Shaft Mixers enhances operational safety by preventing dust leakage. This feature not only maintains a clean working environment outside the mixer but also ensures that the mixing process remains uncontaminated within.

Mixer Interlock Controls

Mixer interlock controls are incorporated to safeguard personnel from potential exposure to moving parts during operation. This safety feature adds an extra layer of protection, aligning with industry standards and regulations to create a secure working environment.

Access Cover Limit Switches

The implementation of access cover limit switches enhances safety and reliability of the mixer. These switches ensure that the access covers are securely closed during operation, preventing accidental exposure and minimizing the risk of operational disruptions.

Pneumatically Operated Discharge Door

A pneumatically operated discharge door facilitates a fast and efficient material discharge. This streamlines the production process and adds to the overall operational efficiency of operating the mixer.

Shaft Mounted Mixer Drive with Oil-Bath Lubricated Transmission

The shaft-mounted mixer drive with an oil-bath lubricated transmission ensures smooth operation, minimizes wear and tear, and extends the equipment’s lifespan.

Shaft Seal Lubrication System

A shaft seal lubrication system enhances the reliability of the mixer. This system ensures that the seals are adequately lubricated, reducing friction and preventing premature wear, thereby contributing to the mixer’s overall longevity.

Cast Ni-Hard Mixing Paddles and Wall Scraper Blades

Cast Ni-Hard mixing paddles and wall scraper blades are designed to resist abrasion and wear. These components provide longevity and reliability in demanding mixing applications. Look for paddle and clades that are designed to be easily replaceable for simplified maintenance over the lifetime of the mixer.

Cast Ni-Hard Liner Segments

Bolted cast Ni-Hard liner segments contribute to the mixer’s overall durability and ease of maintenance. It adds a layer of protection from abrasive materials that can lead to premature wear if not accounted for. The bolted design allows for straightforward replacement, reducing downtime and ensuring that the mixer can consistently deliver optimal performance.

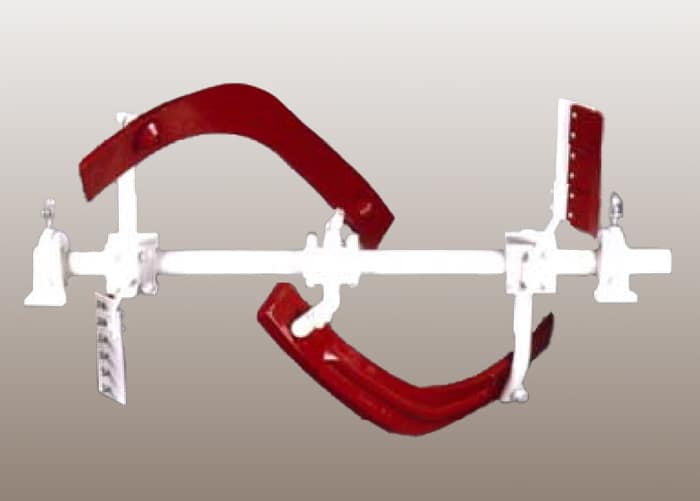

Spiral Mixing Blades Arrangement

Industry proven standard mixing blade arrangement for high production mixing applications. Spiral Mixing Blades deliver a cross current mixing action that constantly forces materials into themselves delivering a thorough, homogenous mix batch after batch.

Horizontal shaft mixers are crucial in mixing product for a wide range of applications including precast, dry bagging, transit mixes and specialty mixes. Looking for these features in your next horizontal shaft mixer will help ensure you will produce high-quality products and help improve operational safety.

For more information or details on how we can help you select the right equipment for your application, contact Wm Neundorfer & Co today.

We have the expertise and experience to ensure you get the advice and recommendations you require for your specific application.