Electromechanical Pan Feeders: What You Need to Know

From steel production to recycling to mining to food, vibratory pan feeders reliably regulate dry bulk materials out of process and storage vessels. Controlling the flow of bulk materials to downstream equipment is critical to ensuring a smooth and well running process. Wm. Neundorfer & Co. has been a long-time partner of JVI Vibratory Equipment, a manufacturer specializing in single mass electromechanical vibratory pan feeders. In this article we will cover what an electromechanical pan feeder is, where they are used, and the benefits they provide.

What is an Electromechanical Pan Feeder?

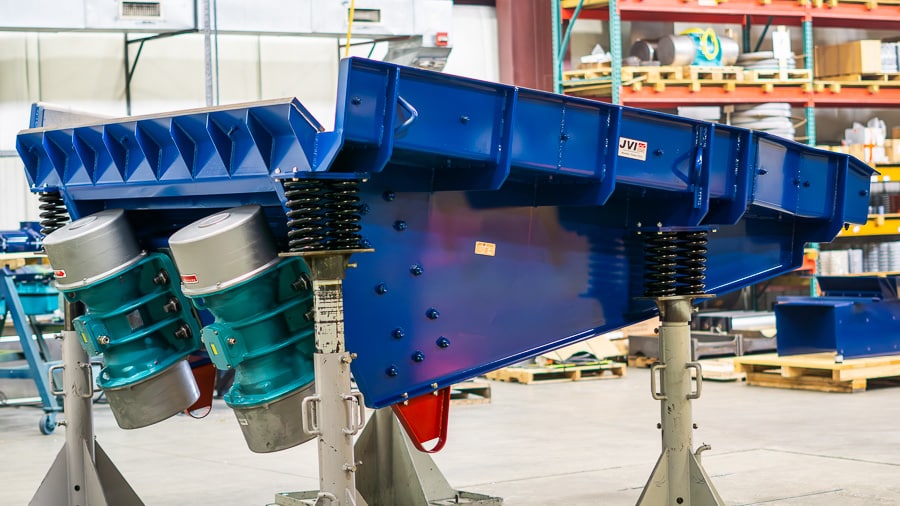

An electromechanical pan feeder’s primary function is to regulate feed rates of dry bulk solid materials out of hoppers at a specific volumetric rate. They are typically constructed of carbon steel and utilize unbalanced motors to create the vibration necessary to move material across the pan. A good way to think of them is as a valve controlling the movement of material to downstream equipment. When the feeder is running the valve is open and when the feeder is stopped the valve is closed.

Where are Electromechanical Pan Feeders Utilized?

Electromechanical feeders are widely used in various applications including discharging truck dump stations, rail dump stations, reclaim piles, silos, hoppers, and other storage vessels. They are used to regulate the flow of materials to downstream crushers, mixers, belt conveyors, screeners, dryers, etc. These versatile machines are found across a wide range of industries including:

- Aggregates

- Steel

- Recycling

- Energy

- Food

- Agriculture

- Mining

- Plastics

- Chemical

- And many more

Benefits of Electromechanical Pan Feeders

Customizable to Your Process

Electromechanical pan feeders can be manufactured in many different pan configurations and materials of construction. From stainless steel pans for food grade applications to explosion proof motors for hazardous areas, these feeders can be customized to the application’s specific requirements. These customizations include static chute works, wear liners, stands, adjustable bed depth gates, and more.

Less Sensitive to material changes:

Our partners at JVI specialize in electromechanical pan feeders that utilize a single mass technology. This technology eliminates sensitivity to material changes, such as moisture content that causes sticking to the pan, that add weight to the overall vibrating mass. Single mass feeders are not tuned to a natural frequency like traditional dual mass systems. This keeps their stroke consistent and does not put additional stress on the feeder pan. This allows the feeder to continue to work without the need to constantly adjust the tunning. This gives them a significant advantage in applications where the bulk material is exposed to the elements and subject to moisture changes.

Enhanced Feed Rate Adjustability:

Single mass electromechanical feeders do not require natural frequency tuning and are able to be adjusted across are wider frequency rate than a two-mass design can. This equates to greater turndown, feed rate adjustability, and process flexibility through a standard variable frequency drive (VFD). Additionally, the feeder can be tied into automated processes based on downstream and/or upstream equipment through that same VFD.

Electromechanical pan feeders represent a versatile and efficient solution for a multitude of industrial applications. Their ability to be customized to specific process requirements, coupled with their resilience to material changes and enhanced feed rate adjustability, makes them an invaluable asset in material handling operations. With their robust and maintenance-free design, these feeders ensure consistent performance and reliability, making them a preferred choice across various industries. For more information on how electromechanical pan feeders can benefit your operations, reach out to Wm. Neundorfer & Co. today.

For more information or details on how we can help you select the right equipment for your application, contact Wm Neundorfer & Co today.

We have the expertise and experience to ensure you get the advice and recommendations you require for your specific application.