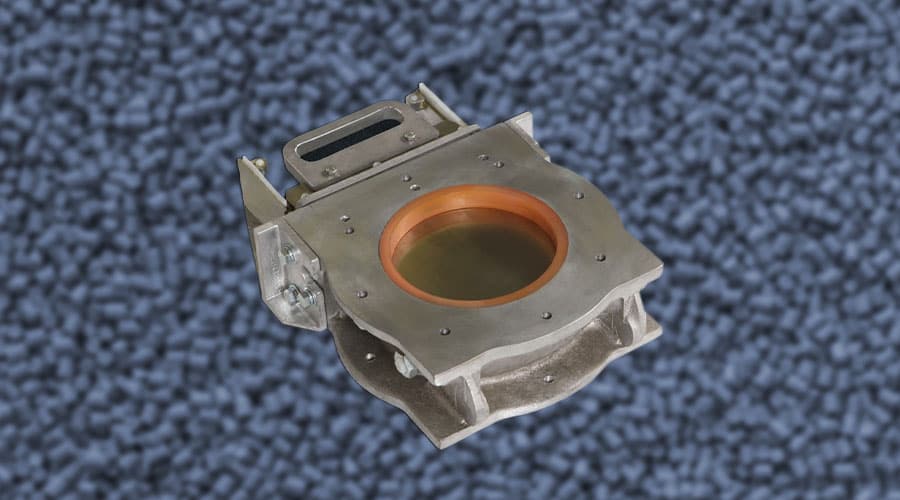

Slide Gate Valves: Control Dry Bulk Materials

Slide gate valves are an important part of industrial processes that handle dry bulk materials. They provide operators with the ability to control the flow of material to downstream equipment. Wm. Neundorfer & Co. has helped our customers control the flow of dry bulk materials in their plants and facilities with our lines of gates, valves, and diverters. In this article we will explore what slide gate valves are and the advantages they provide.

What is a Slide Gate Valve?

Slide gate valves are linear motion valves that are used to regulate the discharge of bulk materials from storage vessels. They operate by sliding a plate or disk across the flow of material to shut off the flow of material from moving through.

Advantages of Slide Gate Valves

These valves offer several benefits that make them suitable for specific uses cases. Here are some key advantages of slide gate valves:

Quick Shutoff:

Slide gate valves provide rapid and reliable shutoff capabilities. Their design allows for a tight seal, effectively stopping the flow of materials when the valve is closed. This is crucial in emergencies or situations requiring quick isolation of a section of the system.

Low Pressure Drop:

Slide gate valves typically exhibit low pressure drop when fully open. This characteristic is advantageous in applications where maintaining a consistent flow rate and minimizing energy consumption are priorities.

Material Versatility:

These valves can handle a wide range of materials, including liquids, powders, slurry, and other fluid or solid media.

Minimal Maintenance:

Slide gate valves are known for their simplicity and robust construction, leading to reduced maintenance requirements. The minimal number of moving parts contributes to lower wear and tear, resulting in longer service life and decreased downtime.

Bidirectional Flow:

Slide gate valves are often designed to allow bidirectional flow. This flexibility is valuable in applications where the direction of flow may need to be reversed.

Compact Design:

The compact design of slide gate valves makes them suitable for installations where space is limited. This can be advantageous in applications where the available work envelope is limited.

Abrasion Resistance:

In applications where materials with abrasive properties are handled, such as in mining or wastewater treatment, slide gate valves can be fitted with wear-resistant materials that can extend the operating life of the gate.

Automation Compatibility:

Many slide gate valves are designed to be compatible with automation systems. This allows for remote operation, integration into control systems, and the ability to optimize valve positions based on process requirements.

Cost-Effective Solution:

Slide gate valves are a cost-effective solution for applications that demand reliable on/off functionality. Their relatively simple design and ease of maintenance contribute to cost savings over the valve’s lifecycle.

Various Actuation Options:

Slide gate valves can be actuated manually, pneumatically, or electrically, providing flexibility in choosing the most suitable actuation method for a particular application. This adaptability contributes to their widespread use in different industries.

Slide gate valves are a reliable and versatile solution for controlling the flow of materials in industrial processes. They provide a cost-effective solution for operators who are looking to take control of their processes.

For more information or details on how we can help you select the right equipment for your application, contact Wm Neundorfer & Co today.

We have the expertise and experience to ensure you get the advice and recommendations you require for your specific application.